-

1894:

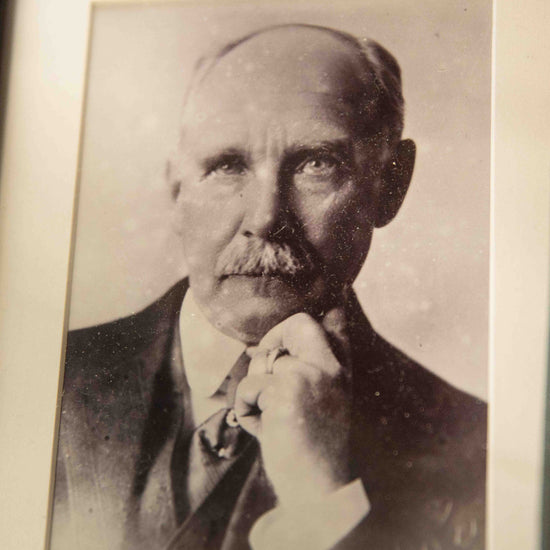

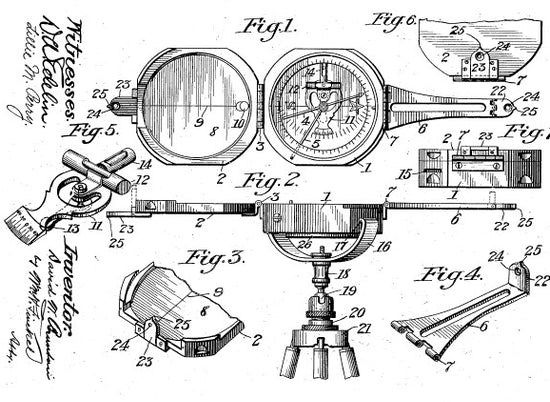

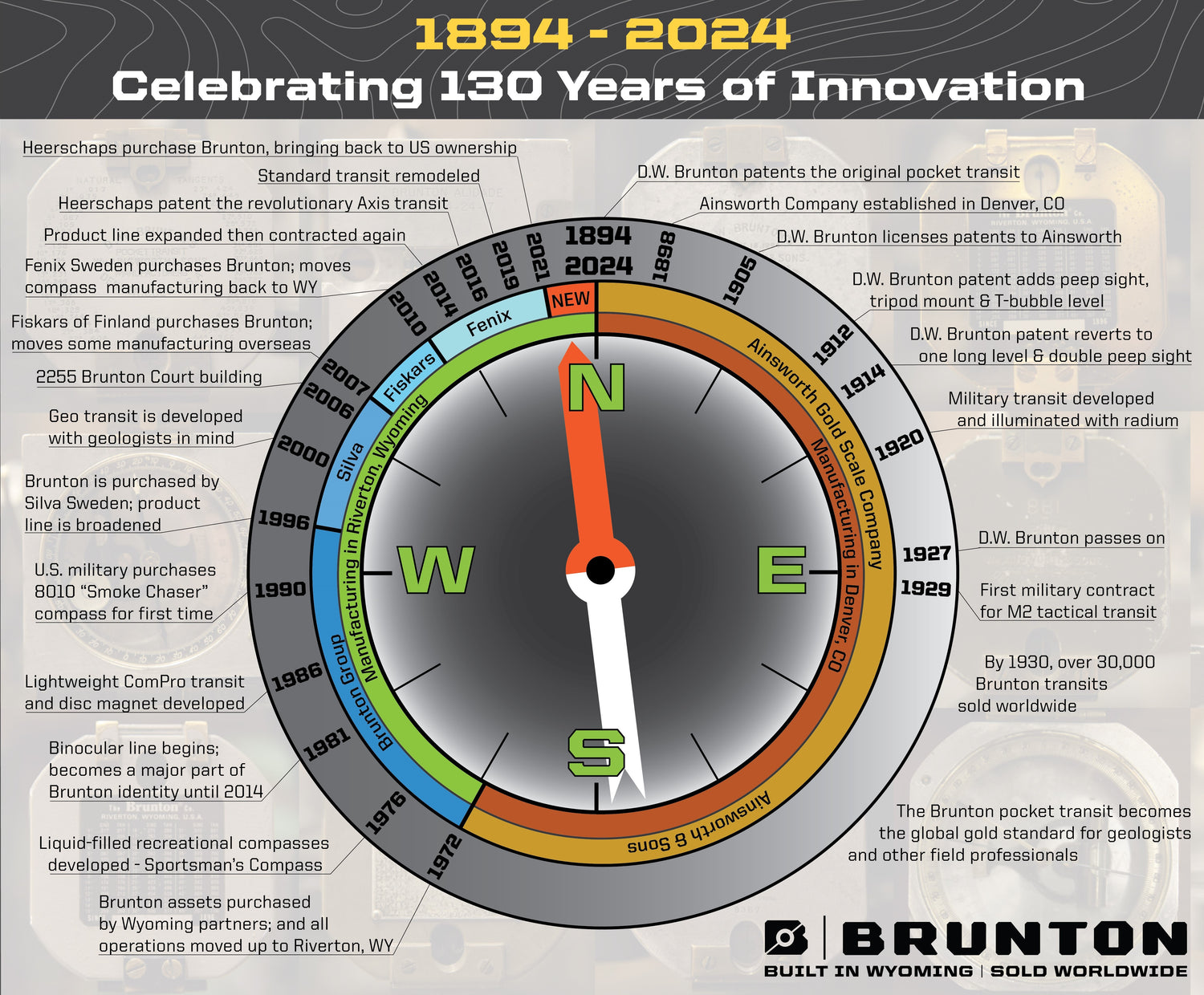

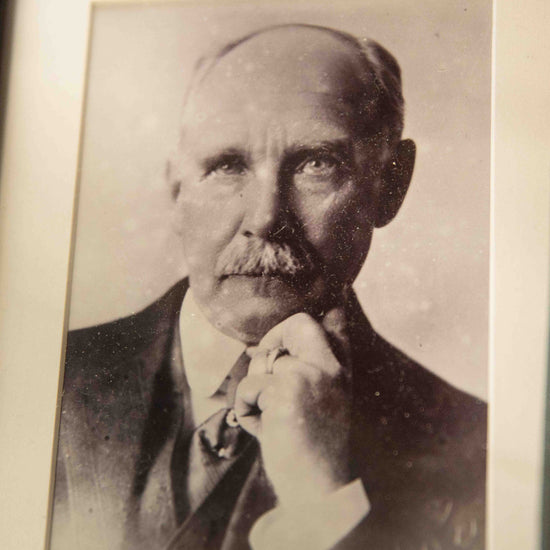

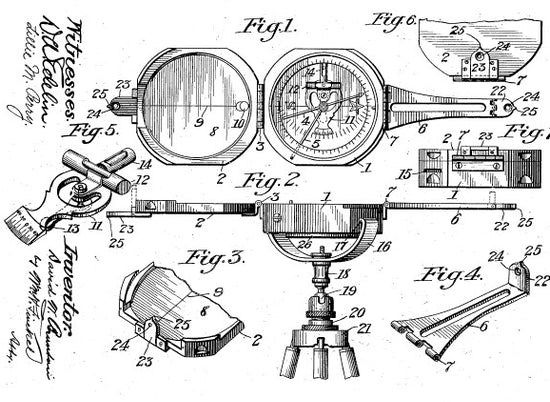

The name “Brunton” comes from D.W. Brunton, the original inventor of the now internationally famous pocket transit. D.W. Brunton was a Canadian mining engineer working in Aspen, Colorado. Brunton designed a portable, compact version of the bulky surveying transits used at the time, and he was awarded the original pocket transit patent on September 18, 1894. He licensed his patent to watchmaker William Ainsworth of Denver, CO, and the pocket transit quickly became the favored tool of geologists and other field professionals around the world.

-

1912-1926:

D.W. Brunton patented several additional innovations on his pocket transit design, improving upon leveling, sighting, and tripod-mounting capabilities. Through his involvement in World War I, Brunton adapted the pocket transit to military use, adding illumination and additional mapping adaptations. He continued innovating until his death in 1927, and his transit designs continued to be manufactured by the Ainsworth & Sons company in Denver. By the late 1920's, about 30,000 Brunton pocket transits had been manufactured and sold worldwide.

-

1929:

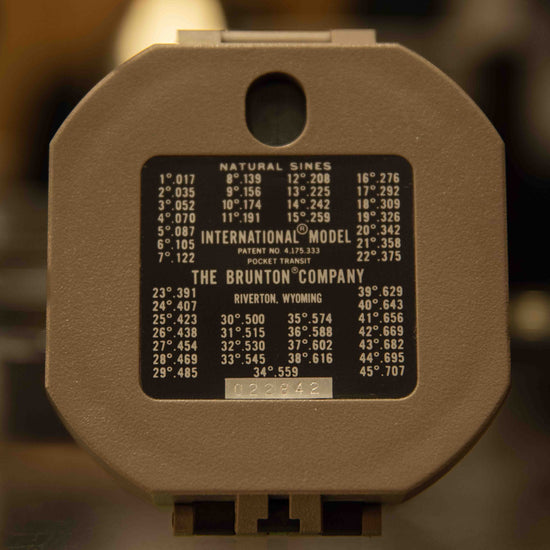

The U.S. military ordered the first batch of pocket transits adapted for various peace-time and war-time uses. Ainsworth & Sons continued to manufacture and market the pocket transit for various uses in the field. Now called the M2 transit, this military adaptation and its associated government contracts continue to be an important market for Brunton to this day.

-

1972:

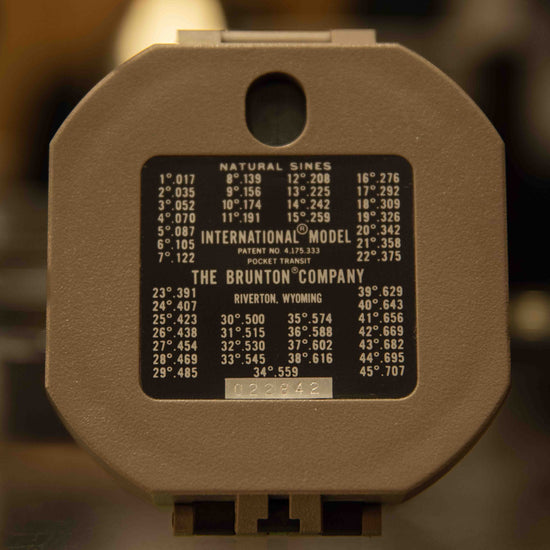

A group of Wyoming businessmen from Riverton combined their resources and purchased the Brunton brand and line of products from Ainsworth & Sons, moving the company’s production and management headquarters to Riverton, Wyoming where manufacturing has been ever since.

-

1986:

A lightweight composite version of the pocket transit called the ComPro was developed. This model also included improved water-resistance and a new magnetic disc needle made of cast NdFeB.

-

-

1996:

Brunton was purchased by Silva Production AB, a Swedish company who was mainly manufacturing maritime compasses and foul weather gear. With that merger, Brunton expanded its compass line and added early GPS, inclinometers, sighting compasses, headlamps, pedometers, and more.

-

-

2000:

Through the early 2000’s, the Brunton product line continued to expand, this time into the portable power, camp stove, and heat source realms for high-end camping. Brunton also developed the Geo Transit, the first innovation specific to geological uses of the traditional pocket transit.

-

2006:

To help ensure Brunton's longevity in Wyoming and keep its manufacturing and management from going overseas, another community effort resulted in the construction of a new state-of-the-art facility to house Brunton's production and management.

-

2007:

Fiskars of Finland acquired Silva, and a few additional products such as monoculars were added to the line. While Brunton continued to manufacture professional transits in Riverton, WY, much of the rest of the product line was manufactured in China during this time.

-

2010:

Fenix of Sweden acquired Fiskars and cut off ties to the Silva/Fiskars compass lines. Almost all production was brought from China back to Riverton. Portable power, heat sources, and lighting were rapidly expanded between 2010 and 2016, then the brand consolidated back to its core line of precision portable navigation and measurement products. Brunton operated in combination with Primus under the name Brunton Outdoor, Inc. with production in Riverton, WY and headquarters/shipping in Louisville, CO within the Fenix N.A. headquarters. Leadership and ownership of the brand was located in Sweden.

-

2016:

The Axis transit entered the market as the first significant redesign of the pocket transit and its measurement methods since 1894. Invented and patented by geologists/educators Lauren and David Heerschap, the unique Axis hinge makes it the only transit in the world that can take simultaneous measurements of planes or lines.

-

-

2019:

The traditional models of pocket transits are upgraded to the Standard Transit, making all of Brunton's metal body transits CNC-milled and anodized rather than the former painted cast aluminum. This change improved the efficiency and environmental footprint of transit manufacturing.